We offer the following thermography courses

Infrared Certification Training

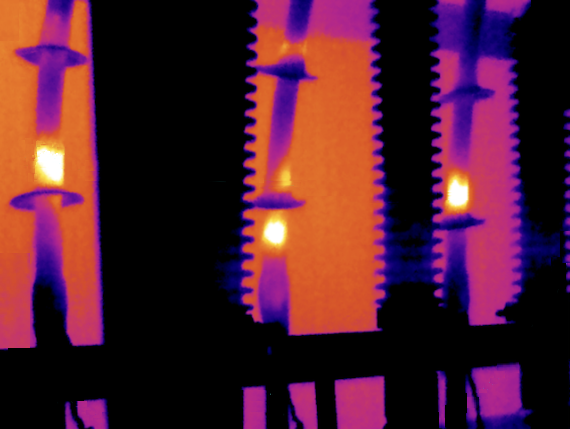

Level I you will: Electrical discharges from high voltage substation components can be detected by capturing temperature variations caused by partial and total discharges.

Level II you will: Infrared thermography detects abnormal temperature patterns associated with aggressive discharging known as arcing and allows for early identification and preventive action to avoid equipment damage and power disruptions.

Level III you will: By identifying temperature variations in loose electrical components, timely maintenance can be scheduled to prevent damage from overheating and potential equipment failure. This early detection helps prevent power disruptions, ensuring the reliability of aging electrical grids.

What have people said after taking this course?

"To be able to take courses at my own pace and rhythm has been an amazing experience. I can learn whenever it fits my schedule and mood."

"To be able to take courses at my own pace and rhythm has been an amazing experience. I can learn whenever it fits my schedule and mood."

"To be able to take courses at my own pace and rhythm has been an amazing experience. I can learn whenever it fits my schedule and mood."

Need more information on infrared training?

Contact our experts for additional information and a quote.

Infrared for Electrical Applications

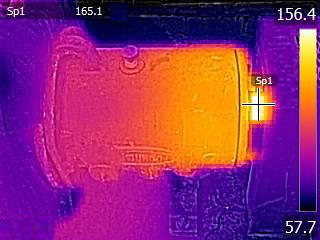

Infrared imaging detects overheating components, such as bearings or windings, in large electric motors. Elevated temperatures can be detected in bearing areas, enabling early identification of potential failures. This proactive approach allows for targeted maintenance, preventing excessive wear and ensuring motor reliability. By capturing thermal patterns in motor windings, infrared thermography identifies overheating, facilitating early detection of insulation issues. This allows the scheduling of proactive maintenance to prevent winding failures, maintain motor efficiency, and extending the lifespan of the motor.

Need training to inspect your high voltage substation?

Pacific Reliability helped our facilities find problems with our high voltage critical assets- I highly recommend them as a premier provider!" CA Utilities Provider Sr. Reliability Engineer

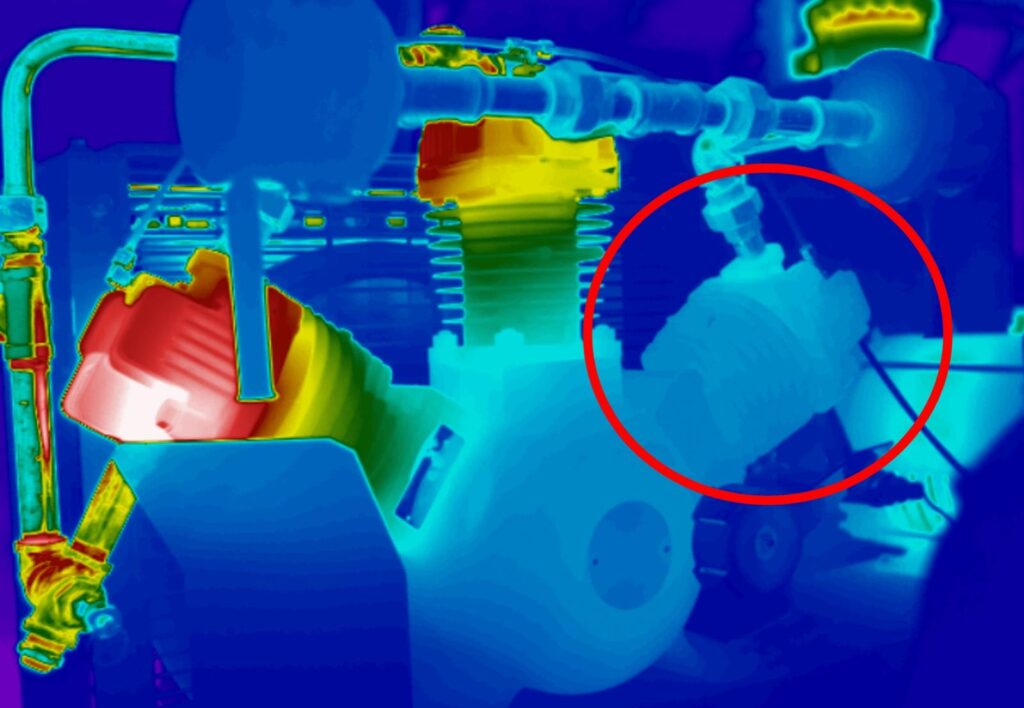

Infrared for Mechanical Applications

Learning Outcomes

Level I you will: Electrical discharges from high voltage substation components can be detected by capturing temperature variations caused by partial and total discharges.

Level II you will: Infrared thermography detects abnormal temperature patterns associated with aggressive discharging known as arcing and allows for early identification and preventive action to avoid equipment damage and power disruptions.

Level III you will: By identifying temperature variations in loose electrical components, timely maintenance can be scheduled to prevent damage from overheating and potential equipment failure. This early detection helps prevent power disruptions, ensuring the reliability of aging electrical grids.

Need training to inspect your critical mechanical assets?

Contact our experts for additional information and a quote.

Infrared for High Voltage Substations

Learning Outcomes

Level I you will: Electrical discharges from high voltage substation components can be detected by capturing temperature variations caused by partial and total discharges.

Level II you will: Infrared thermography detects abnormal temperature patterns associated with aggressive discharging known as arcing and allows for early identification and preventive action to avoid equipment damage and power disruptions.

Level III you will: By identifying temperature variations in loose electrical components, timely maintenance can be scheduled to prevent damage from overheating and potential equipment failure. This early detection helps prevent power disruptions, ensuring the reliability of aging electrical grids.

Need training to inspect your high voltage substation?

Contact our experts for additional information and a quote.

Our Training Benefits

As world-renowned experts in infrared thermography training, we have gathered unparalleled experience in enhancing equipment reliability and site safety across a wide range of industries throughout the Americas and the Caribbean.

Our on-site training aligns with NFPA, ANSI, ASNT, NETA, NESC, and OSHA standards, offering immersive, hands-on instruction for various technical levels. We integrate with each facility's safety and operational protocols, enhancing reliability and ensuring safety compliance.

How we develop your training solutions

The steps to begin learning how to implement infrared thermography at your facility today:

- Contact Us: Share details about your specific industry and training needs.

- Assessment of Needs: Our experts will contact you to assess your team, equipment and business requirements.

- Tailor your Program: The training material will be delivered to suit your team's skill level, and aligned with your specific needs.

- Scheduling: We'll coordinate to ensure minimal disruption to your operations.

- Onsite visit: Our expert trainers provide hands-on training to ensure maximum learning.

By following these steps, you will benefit from the best customized, practical learning experience directly on your production equipment.

Learn how our training can transform your organization

Speak to a subject matter expert now!

In each case, the non-contact nature of infrared thermography allows for inspections to be conducted while equipment is in operation, eliminating the need for downtime. The technology's precision in detecting subtle temperature variations provides engineers with actionable insights, enabling them to address potential problems before they escalate, ultimately enhancing the overall reliability and efficiency of industrial equipment.

Next Steps

Elevate your workforce's capabilities with our comprehensive infrared thermography training. Empower your team to proficiently assess industrial equipment, identify potential issues, and optimize maintenance practices. Join our expert-led program now to ensure a skilled workforce, enhancing operational efficiency, reducing downtime, and safeguarding critical assets for long-term reliability and cost-effectiveness.

Need more info?

Take command of your success by leveraging our training expertise and experience in your industries: Aerospace, Agriculture, Defense, Energy, Food & Beverage, Manufacturing, Mining, Nuclear, Paper & Pulp, Petroleum, Pharmaceutical, Semi-Con, Solar Energy, Transportation (Air & Rail), Waste Water Treatment, Wind Farms and many more.

Enquire today and we will help tailor a solution built to empower your workforce and meet the business challenges to propel your success to new heights.